How an electric car works: An overview of the technical component

Electric cars are becoming increasingly popular due to their environmental friendliness and efficiency. However, in order to understand why they work the way they do, it is worth understanding their technical structure. In this article, we'll look at the main components of an electric car, their functions, and how they work. We remind you that you can buy both home and commercial charging stations in our online store, [...]

Content:

Electric cars are becoming increasingly popular due to their environmental friendliness and efficiency. However, in order to understand why they work the way they do, it is worth understanding their technical structure. In this article, we'll look at the main components of an electric car, their functions, and how they work. We remind you that you have the opportunity to purchase both home and commercial charging stations in our online storeand use our public charging stations ECOFACTORlocated throughout Ukraine. For easy access to charging, you can use our applicationavailable for the following platforms iOS and Android.

Rechargeable battery

The battery is the main component of an electric vehicle, as it is the key to its ability to operate and its autonomy. It stores the energy that the engine uses to propel the vehicle. Understanding how batteries work and the types of batteries available helps you better understand why electric vehicles are so efficient and promising.

Types of batteries in electric cars

Batteries for electric vehicles are mainly divided into several types depending on their chemical composition and design. The most common are lithium-ion and lithium-polymer batteries, but there are other options that are less commonly used. Here's a closer look at the main types:

Lithium-ion batteries

Lithium-ion (Li-ion) batteries are the most popular due to their high energy capacity, durability and ability to be recharged for a large number of cycles. They are composed of positive electrodes, negative electrodes and electrolyte, which allows them to store a large amount of energy in a compact area. Lithium-ion batteries have the following advantages:

- High power consumption: They are able to store large amounts of energy compared to other types of batteries.

- Lightweight and compact: Lower weight compared to other battery types, which is important for reducing the overall weight of the vehicle.

- Long service life: Lithium-ion batteries can last up to 8-10 years with proper care.

Lithium-polymer batteries

Lithium polymer batteries are similar to lithium-ion batteries, but their design allows for greater flexibility in shape and size. This is particularly useful in the design of electric vehicles, where space optimisation is important. They have the following advantages:

- Design flexibility: The ability to manufacture batteries in various shapes and sizes.

- Less tendency to overheat: This makes them safer to operate.

- Long service life: Similar to lithium-ion batteries, they can last up to 8-10 years.

Solid-state batteries

Solid-state batteries are the latest technology based on the use of a solid electrolyte instead of a liquid or gel. They promise significant improvements in efficiency, safety and energy capacity, but are currently only used in prototypes and are expected to be introduced into commercial production in the coming years.

How are the batteries charged?

The battery in an electric vehicle can be charged in different ways, depending on the type of charger and the capabilities of the vehicle itself. The main types of chargers:

- Standard home sockets: This is the slowest charging method, but it is suitable for overnight charging. Typically, you can get 8-12 km of range per hour of charging using a standard wall socket.

- DC fast charging stations: They allow for significantly faster battery charging and provide the 80% with a charge in 30-40 minutes.

- Medium charging stations (AC charging): They are a balance between speed and efficiency, delivering a full charge in 4-6 hours.

Charging time

The battery charging time depends on several factors, including battery capacity, type of charging station, and other characteristics. For example:

- Fast charging At special stations, it can take only 30-60 minutes for the 80% to receive a charge.

- Charging from a standard power outlet takes much longer - up to 12 hours to fully charge.

High power consumption and range

The main advantage of batteries for electric vehicles is their ability to provide a significant range. Modern batteries can provide between 200 and 600 km of range on a single charge, depending on the capacity and efficiency of the battery. Most entry-level cars have a range of around 250-350 km, while more expensive models have a range of over 500 km.

How do I care for my battery?

To ensure that the battery lasts as long as possible, it is important to charge and store it properly:

- Do not allow the battery to be completely discharged: It is best to charge it up to 20-80% for maximum life.

- Do not overheat the battery: High temperatures can shorten the life of the battery.

- Do not leave the vehicle at a very low charge level for a long time: Doing so may damage the battery.

Advantages and disadvantages of battery technology

Advantages:

- Environmental friendliness: Batteries do not emit CO2 emissions, which significantly reduces the environmental impact.

- Minimal maintenance costs:: Compared to conventional cars, electric cars do not require frequent replacement of engine or transmission parts.

- Quiet operation: The absence of engine sounds makes for a more comfortable and relaxing ride.

Disadvantages:

- The cost of replacing the battery: Replacing the battery can be expensive.

- Dependence on charging infrastructure: Not all regions have enough charging stations, which can be a problem when travelling long distances.

The battery is an integral part of an electric vehicle that determines its efficiency and functionality. Thanks to technologies such as lithium-ion and lithium-polymer batteries, electric vehicles have a high energy capacity and a long service life. However, in order to get the most out of them, it is important to use and maintain the batteries properly.

Electric motor

The electric motor is the main element that converts the electrical energy from the battery into mechanical energy, which is needed to propel an electric vehicle. Compared to traditional internal combustion engines, electric motors have a number of advantages, including high efficiency, less wear and tear, and no pollution. Understanding how an electric motor works allows you to better appreciate its importance in the structure of an electric vehicle.

How does an electric motor work?

An electric motor is based on the interaction of magnetic fields created by an electric current. The principle of operation can be viewed through several main stages:

- Electric current: When a current passes through a coil of wire (which is located in a magnetic field), it creates a magnetic field that interacts with the field of permanent magnets or coils. This interaction causes a force that makes the coil move.

- Rotation: A rotating coil transmits mechanical energy to a shaft, which can then transmit motion to the wheels or other parts of the vehicle.

The electric motor in electric cars is mostly alternating current (AC), although some models also use permanent magnet or direct current (DC) motors.

Types of electric motors in electric cars

There are several main types of electric motors used in electric vehicles. Each has its own characteristics that make it suitable for different needs and car models.

Direct current (DC) motors

These motors are easy to use and allow for precise speed control. They are used in some older electric cars or in low-cost models. However, they are less efficient than other motor types.

AC Induction Motors

Induction motors are the most common motor type for modern electric vehicles. They are low in cost, simple in design and highly reliable. One of the key advantages of an induction motor is that it does not require the use of rare earth materials, which makes it more affordable and less expensive than other options.

Permanent magnet synchronous motors (PMAC)

Permanent magnet synchronous motors are used in more expensive and powerful electric vehicles such as Tesla. They are more efficient and able to achieve higher power at a lower weight, making them optimal for vehicles that require a greater range and power output.

Advantages of electric motors

Electric motors have several obvious advantages over internal combustion engines:

Higher efficiency

Electric motors are much more efficient than internal combustion engines because more of the energy from the battery is converted into useful work. This means lower energy costs and more range per charge.

No contamination

Electric motors do not need to burn fuel, so they do not emit harmful emissions such as CO2 or nitrogen oxides, making electric cars significantly more environmentally friendly.

Easy to maintain

Electric motors have fewer moving parts than internal combustion engines, which reduces the likelihood of breakdowns and maintenance. This also means lower repair costs and a longer service life.

Torque and torque performance

Electric motors have the ability to generate torque as soon as they start, which gives electric vehicles extremely fast start-up and high dynamics.

How is the speed controlled?

One of the main characteristics of electric motors is the ability to smoothly adjust the speed without the need for a transmission, which is typical for cars with internal combustion engines. In electric vehicles, the speed is changed by an electronic control unit (ECU) that regulates the current flow to the motor. This allows for smooth acceleration without jerking and reduces the number of mechanical parts that wear out.

Features of the electric motor in electric cars

- Low noise level: Electric motors are significantly quieter than internal combustion engines. This improves driving comfort and reduces noise pollution.

- High torque at low speeds: With electric motors, the maximum torque is available at low speeds, which allows for better starting dynamics.

- Compact and lightweight: They are lighter in size and weight, which contributes to better space saving and reduced vehicle weight.

The electric motor is the basis of propulsion for modern electric vehicles, providing high efficiency, quiet operation and instant torque. It not only reduces maintenance costs, but also makes the vehicle more environmentally friendly. Modern technologies allow for continuous improvement of these motors, making them even more efficient and powerful.

Transmission and drive system

The transmission and drive system are important components of an electric vehicle's design, although their role is quite different from that of traditional internal combustion engine vehicles. Whereas internal combustion engines require complex transmissions with multiple gear ratios to optimise power and speed, electric vehicles mostly use simpler, more efficient systems that greatly simplify the design and improve efficiency.

The role of the transmission in electric vehicles

In classic cars, the transmission plays a crucial role in transferring power from the engine to the wheels. Since the internal combustion engine operates in a limited speed range, the need for gears is driven by the need to adapt to different driving conditions (starting, accelerating, driving at high speed). In electric vehicles, the situation is somewhat different.

How an electric car's transmission works

Electric motors have a very wide rev range and are able to operate efficiently over a wide range of speeds without the need to change gears. This is made possible by the unique characteristics of an electric motor: it does not need to change speed to provide optimum torque in any speed range. For this reason, most electric vehicles are equipped with a single-speed transmission.

A single-speed transmission in an electric car is a fairly simple system that transfers rotation from the engine to the wheels. It does not have a traditional gearbox and does not require a complex clutch system, as is necessary for cars with an internal combustion engine. This significantly reduces the number of mechanical components, reduces wear and tear, and increases reliability.

Drive system: one or two motors?

Electric cars can have different types of drive, depending on the number of electric motors used to drive the wheels:

Single wheel drive (RWD or FWD)

Many electric vehicles use a single-wheel drive system - either rear-wheel drive or front-wheel drive (RWD or FWD). This is usually the case with models that use a single electric motor that transmits torque to one axle.

- Rear-wheel drive (RWD) - The electric motor is located on the rear axle, which ensures good manoeuvrability and driving efficiency. This type of drive is often used in electric sports cars and some sedans.

- Front-wheel drive (FWD) - the electric motor is mounted on the front axle, which makes the car more stable on slippery roads. This scheme is often used in budget models.

Four-wheel drive (AWD)

Four-wheel drive provides improved traction, especially on slippery surfaces. Such vehicles typically have two electric motors: one on the front axle and one on the rear axle. Each motor transmits torque to the front or rear wheels, respectively, allowing for efficient power distribution depending on driving conditions.

Such drive systems provide greater stability and control over the vehicle, which is especially important when driving in difficult weather conditions or off-road.

Advantages and disadvantages of different transmission and drive types

Single-speed transmission

Advantages:

- Easy to construct and maintain.

- Higher reliability thanks to fewer moving parts.

- Lower power consumption for the transmission, which allows for longer range on a single charge.

- Silent operation, as there is no gearshift mechanism.

Disadvantages:

- Limitations in maximum power output, as the transmission does not allow for torque optimisation at different speeds, although this is not sufficient for most applications.

Single wheel drive (RWD or FWD)

Advantages:

- Simplicity and low cost of construction.

- Fewer drive elements, which reduces the likelihood of breakdowns.

- Good energy savings as the power is transferred to one axle.

Disadvantages:

- May be less stable in bad weather conditions or when driving off-road, especially with front-wheel drive.

Four-wheel drive (AWD)

Advantages:

- Improved stability and grip.

- Better manoeuvring on slippery roads or off-road.

- The power distribution between the axles helps to make even use of all available energy.

Disadvantages:

- Greater complexity of construction and maintenance.

- Higher energy consumption due to two motors.

- May be more expensive than models with single axle drive.

Integration of powertrain and drive train into electric vehicles

Modern technology allows the transmission and drive system to be integrated in such a way as to maximise the power of electric motors. Some vehicles use advanced control systems that automatically adjust the distribution of power between the front and rear axles, which helps to maintain high efficiency even in difficult conditions.

For example, Tesla uses a dual-motor system with one motor on the front axle and one on the rear axle, which not only provides power for maximum acceleration but also maintains a high level of stability in all conditions.

The transmission and drive system of an electric vehicle are among the most important components that determine its efficiency, comfort and safety. Single-speed transmissions and systems with electric motors on one or two axles can significantly simplify the design and reduce maintenance costs. The choice of drive train and transmission type directly affects the vehicle's performance, and each type has its own advantages depending on the operating conditions and driver needs.

ECOFACTOR: Partner in the world of electric vehicles

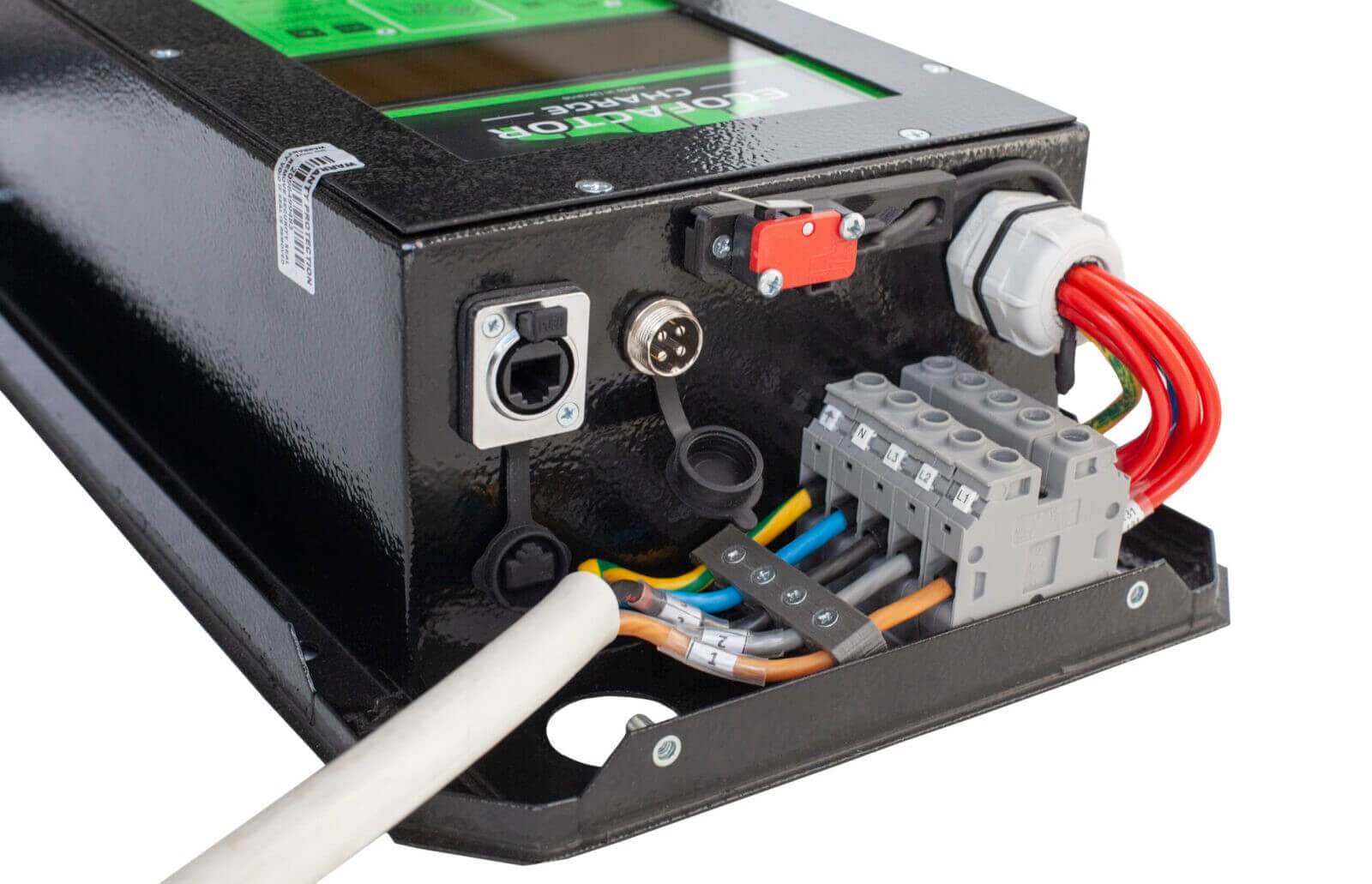

In today's world, electric vehicles are not only an eco-friendly solution, but are also becoming an integral part of global changes in transport infrastructure. They offer significant benefits, such as reduced emissions, lower noise pollution and lower operating costs compared to conventional vehicles. We are in ECOFACTOR At Vickers, we understand the importance of the technology behind every electric vehicle and are actively seeking to be part of this transformation. Our charging and energy management solutions create additional benefits for drivers, helping them to maximise the potential of their electric vehicles, increasing their autonomy and convenience. Our cables and adapters comply with the most advanced European quality standards, which guarantees safe, fast and efficient charging of your electric vehicles.

As a company specialising in the development of innovative, environmentally friendly technologies, we offer reliable, fast and safe solutions for charging electric vehicles. Our charging stations not only meet the highest safety standards, but also optimise the charging process, saving energy and time. The energy monitoring platform allows real-time monitoring of the charge level and prediction of the time required to complete the charging process. These technologies not only increase energy efficiency but also help reduce drivers' charging costs, which is an important component of operating expenses. At the same time, we provide the ability to integrate with ECOFACTOR mobile application for iOS and AndroidThe newly developed charging system enables drivers to manage their vehicle charging from a distance, adding convenience and flexibility to their daily routine.

ECOFACTOR is actively working on the development of infrastructure for electric cars, creating map of charging stationsThe company has developed a range of charging solutions that allow drivers to not only charge their vehicles efficiently, but also have access to safe and convenient technology. Here are some of the key benefits of our solutions:

- Fast charging: Our stations provide fast and efficient charging, which saves drivers time.

- Real-time monitoring: The system allows you to monitor the charge level and power consumption status, which allows you to optimise energy use.

- Mobile application: the ability to control charging from a distance via an intuitive app, which adds convenience.

- Security: All our charging stations meet international safety standards, which guarantees reliability and durability.

- Accessibility: Our network of charging stations is expanding to provide convenient access to energy resources across the region.

We are making an important contribution to the preservation of the environment while increasing the convenience and accessibility of electric vehicles for users. As a result, we contribute to the sustainable development of environmentally friendly transport by improving the driver experience and reducing the environmental impact.

Energy recovery system

The energy recovery system in electric vehicles is one of the most important innovations that conserve energy and improve vehicle efficiency. It converts kinetic energy, which is usually lost during braking, back into electrical energy to charge the battery. This helps to increase the vehicle's range and reduce overall energy consumption, which is essential for electric vehicles.

How the energy recovery system works

The energy recovery system, or regenerative braking, works by using the electric motor as a generator during braking or deceleration. When the driver applies the brake or releases the accelerator, the system automatically activates the electric motor, changing its function from drive to generator. This process converts the kinetic energy that the vehicle loses during braking into electrical energy that can be stored in the battery.

Stages of recovery

- Slowing down the movement: During deceleration or braking, the engine starts to work as a generator, where mechanical energy is transferred into electrical energy.

- Conversion of kinetic energy: Instead of this energy being used to overcome the friction in the brake pads, it is converted into electrical energy.

- Charging the battery: The energy generated is transferred to the rechargeable battery for further use.

This process significantly reduces the load on the mechanical braking system and reduces component wear.

Types of energy recovery systems

There are several options for regenerative braking, depending on the level of integration and complexity of the system. All of them aim to maximise energy recovery when the vehicle speed is reduced.

Gentle regenerative braking

In systems with soft regenerative braking, energy is recovered only when the brake pedal is lightly applied or the accelerator is released. The driver does not feel a significant change in braking performance, and the system works primarily to maintain battery charging during moderate deceleration.

Advantages:

- Ease of use.

- Minimal change in driving feel.

- Does not require active interaction from the driver.

Disadvantages:

- Low energy recovery efficiency compared to other systems.

Active regenerative braking

Active regenerative braking provides greater energy recovery, especially during heavy deceleration. In such systems, the engine becomes a more active generator, which provides a more noticeable reduction in speed without the use of mechanical brakes. This allows more energy to be returned to the battery, but the driver may experience a noticeable change in braking feel.

Advantages:

- Significantly higher efficiency in energy recovery.

- Reduced wear and tear on mechanical brakes.

- Improved vehicle autonomy thanks to more renewable energy.

Disadvantages:

- It can be unpleasant for drivers due to its strong deceleration without the use of conventional brakes.

- More complexity in management.

Recovery with different intensity levels

Many modern electric vehicles allow the driver to adjust the intensity of regenerative braking using switches or options on the control panel. This allows drivers to choose between different levels of regeneration depending on the driving conditions, allowing them to optimise the process for specific situations.

Advantages:

- Flexibility in settings and the ability to adapt to different conditions.

- Control over energy saving efficiency.

Disadvantages:

- Requires additional driver attention to set up.

Advantages of the energy recovery system

- Increase efficiency: Energy recovery allows for a significant increase in energy efficiency, as a large proportion of the kinetic energy normally lost during braking is reused to charge the battery.

- Reduced energy consumption: This reduces the load on the battery, reducing the need for frequent recharging.

- Reduced brake system wear and tear: Part of the braking force is transferred to the electric motor, which reduces the wear and tear on traditional brake pads and discs.

- Improved battery life: Thanks to renewable energy, the range per charge can be extended, which is particularly important for long journeys.

Disadvantages and limitations

- Dependence on traffic conditions: The effectiveness of regeneration depends on the type of road and traffic speed. In a city with frequent stops and accelerations, regeneration will be more effective than on highways.

- Sensations for the driver: In some systems, intensive regenerative braking can be unfamiliar or even uncomfortable for the driver, especially for those who are not used to changes in the usual braking sensation.

Energy recovery systems are an important element of electric vehicle design, allowing for increased energy efficiency, reduced recharging costs and reduced wear and tear on mechanical brakes. Recovering energy during braking or deceleration is an important step in making electric vehicles more environmentally friendly and economical. Modern systems provide drivers with the ability to adjust the intensity of the regeneration, allowing the technology to be adapted to different driving conditions and styles.

Control system and electronics

The control system in electric vehicles is the central element responsible for optimising the performance of all components of the electric vehicle, from the battery to the electric motor. It includes a variety of electronic components that coordinate various functions, ensure the safety and efficiency of the vehicle, and provide feedback and settings to the driver for comfortable and efficient driving. The control system is critical to ensuring not only the high efficiency of an electric vehicle, but also the safety, convenience and durability of its components.

Architecture of the electric vehicle control system

The control system of an electric vehicle is based on a complex set of sensors, controllers, microprocessors and software that ensures that all components work together in a coordinated manner. The main elements of this architecture include:

- Electronic control unit (ECU): This is the "brain" of the vehicle, which controls all the main functions. The control unit receives data from various sensors (temperature, pressure, speed), processes it and transmits commands to other systems, such as the battery or engine.

- Motor controller: This component is responsible for controlling the performance of the electric motor, optimising its efficiency depending on the power requirement. It regulates engine speed, power and response to the accelerator pedal.

- Driver interface: Modern electric vehicles have interfaces such as touch screens, digital instrument clusters and voice assistants that allow the driver to receive important information about the vehicle's status and interact with various systems.

- Driver assistance systems (ADAS): Most modern electric cars have automatic braking, lane control, and adaptive cruise control systems, which significantly increases safety.

Main functions of the control system

Manage charging and power consumption

One of the main functions of the control system is to monitor the charging and energy consumption processes. This includes monitoring the battery charge level, optimising the charging process to prevent overheating or overloading, and managing power consumption while driving.

- Charging the battery: The control system monitors the voltage and current supplied to the battery to ensure efficient and safe charging. It can also optimise charging depending on the temperature and condition of the battery.

- Energy consumption: The vehicle uses information from various sensors to determine how much energy is required to drive on a particular stretch of road, taking into account driving style, load, road conditions and other factors.

Electric motor control

The control system coordinates the operation of the electric motor to achieve optimum power and efficiency. This component takes into account changes in driving conditions and responds to driver commands, such as increasing speed or slowing down. It ensures even and smooth acceleration and efficient use of battery power.

- Optimising performance: Depending on the power requirement (e.g. when accelerating or driving uphill), the system automatically adjusts the engine to maximise energy efficiency.

- Energy regulation: It can redistribute energy, for example during braking regeneration, to preserve the maximum battery charge.

Security and stability

The control system ensures driving stability and driver safety by using various auxiliary systems:

- Stabilisation systems: Controls wheel traction and helps to avoid slipping, especially on slippery roads.

- Autonomous braking systems: Used to prevent collisions by automatically reducing speed or applying the brakes if necessary.

Communications and software

Modern electric vehicles have built-in communication systems to provide the driver with additional information and access to software updates. This can be a basic infrastructure for remote monitoring, as well as more sophisticated applications for remote battery monitoring, geolocation, or even finding the nearest charging stations.

- Remote update: The system can update the vehicle's software via wireless connections, enabling improved functionality without the need for a visit to a service centre.

- Driver interface: Many electric cars have integrated systems that allow the driver to monitor the battery status, view routes and optimise energy consumption using mobile apps.

Electronics components in an electric car

- Sensors and transducers: Sensors that monitor the vehicle's condition, including battery temperature, speed, battery level, engine load, brake system status and much more, are important elements for data collection.

- Driver interface: The interface includes displays, touch screens, a voice command system and other technologies that allow the driver to interact with the vehicle.

- Security system: Includes a variety of driver assistance systems, from rear-view cameras to full autonomous driving systems such as adaptive cruise control and automatic braking.

The control system and electronics are an integral part of a modern electric vehicle. It not only ensures efficient use of energy, but also plays a key role in ensuring safety, stability and comfort while driving. With the advent of new technologies and innovations in electronics, electric vehicles are becoming increasingly adapted to the needs of the driver, reducing maintenance costs and increasing productivity. Modern control systems are opening up new horizons for the development of intelligent vehicles, leading to their growing popularity and introduction into everyday life.

Conclusion.

An electric car is a complex and high-tech system that combines energy, mechanical and electronic components. Its main advantages are high efficiency, environmental friendliness and minimal maintenance costs. At the same time, to ensure optimal performance, each component must work in sync, which requires precision in settings and integration of technologies.

In summary, electric vehicles are innovative and efficient vehicles that are significantly changing the automotive industry. Their success depends on the development of charging station infrastructure, improvements in battery technology, and the expansion of affordable options on the market.

FAQ

What is energy recovery in electric vehicles?

This is the process by which the energy normally lost during braking is returned to the battery.

What is the difference between electric motors and internal combustion engines?

Electric motors are safe, quiet and highly efficient, while internal combustion engines generate more noise and emissions.

How long does an electric car battery last?

Modern lithium-ion batteries have a service life of up to 8-10 years, depending on the operating conditions.

Can I charge my electric car at home?

Yes, most electric vehicles can be charged via a regular outlet or a special charging station at home.

What is a continuously variable transmission?

It is a transmission system that automatically adjusts power without the use of a traditional gearbox.

What are the advantages of electric cars over petrol cars?

Electric vehicles have low operating costs, are environmentally friendly, highly efficient and do not require frequent maintenance.

Can I use an electric car in cold weather?

Yes, but battery efficiency may decrease in low temperatures.

How fast do electric cars charge?

Charging time depends on the type of charging station and battery capacity. Typically, charging at fast charging stations takes 30-60 minutes.